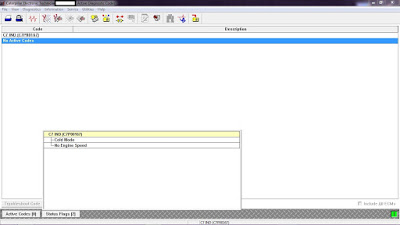

“Cold Mode” and “No Engine Speed” on Status Flags

Cold Mode

-The ECM limits engine power during cold mode operation and the ECM

modifies injection timing during cold mode operation. Cold mode

operation provides the following benefits:

Increased cold weather starting capability

Reduced warm-up time

Reduced white smoke

-The Electronic Control Module (ECM) limits engine power during cold mode operation. The ECM may modify the injection timing and the ECM may cut out certain engine cylinders. This will increase startability and this will reduce warm up time. Cold mode is activated whenever the engine coolant temperature falls below a predetermined value. Cold mode remains active until the engine has warmed or a time limit is exceeded.

Cold Mode Operation

-The ECM will set the cold start strategy when the coolant temperature is below 18 °C (64 °F).

-When the cold start strategy is activated, low idle rpm will be increased to 1000 rpm and engine power will be limited.

-Cold mode operation will be deactivated when any of the following conditions have been met:

Coolant temperature reaches 18 °C (64 °F).

The engine has been running for 14 minutes.

-Cold mode operation varies the fuel injection amount for white smoke

cleanup. Cold mode operation also varies the timing for white smoke

cleanup. The engine operating temperature is reached before the

walk-around inspection is completed. The engine will idle at the

programmed low idle rpm in order to be put in gear.

-After the cold mode is completed, the engine should be operated at low

rpm until normal operating temperature is reached. The engine will reach

normal operating temperature faster when the engine is operated at low

rpm and low-power demand.

No Engine Speed

-It’s normal to see the “No Engine Speed” on Status Flags while power

switched ON or Engine Cranking. It will not go away until the Engine

Starts, even when you are seeing Engine Speed in Status Tool on CAT ET Software.