In the realm of agricultural machinery and engines, efficiency and reliability are paramount. JCB Diagnostic Electronic Service Tool, a cutting-edge diagnostic software, has emerged as a game-changer in the industry. Boasting an intuitive interface and a plethora of features, this software facilitates troubleshooting, maintenance, and fault detection, ultimately enhancing professionalism and instilling trust among customers. In this article, we will delve into the various aspects of JCB ServiceMaster 4, including its features, supported models, system requirements, and hardware compatibility.

Software Information:

JCB ServiceMaster 4 is the latest version of the diagnostic software, released in March 2023. With a file size of 19.7 GB and an installed size of 22.7 GB, it offers comprehensive coverage for JCB agricultural machinery and engines across all regions. The software supports multiple languages, including English, French, German, and Spanish, making it accessible to a wider user base.

Software Features:

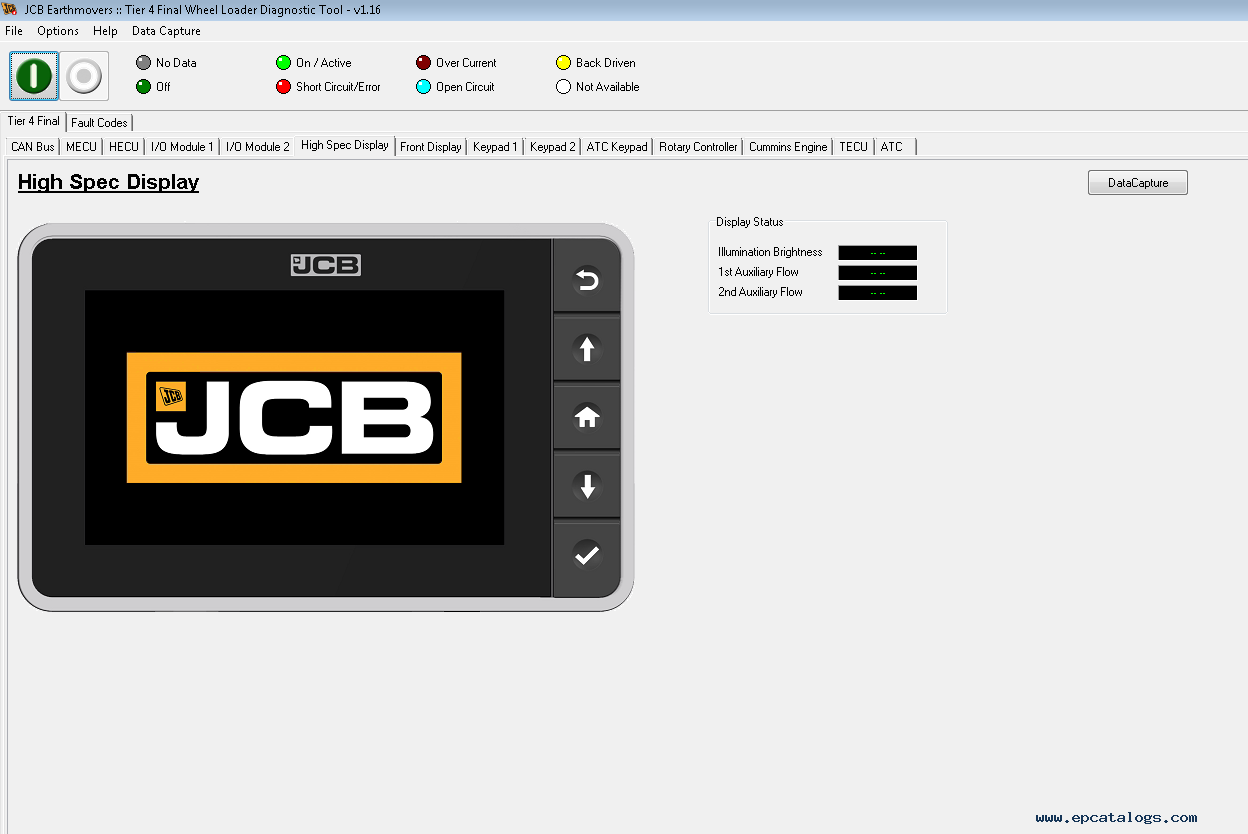

The JCB ServiceMaster 4 software encompasses a range of powerful functions that empower users in their diagnostic endeavors. Some of its key features include:

1. Troubleshooting: The software provides a quick and effective fault-finding mechanism, aiding users in identifying and resolving issues promptly.

2. Standard Test Service: Users can perform standard tests to verify maintenance standards and ensure optimal performance of the machinery or engine.

3. Data Viewing and Editing: JCB ServiceMaster 4 allows users to view and edit generated data, enabling them to make necessary adjustments and modifications as required.

4. ECU Flash Files: The software facilitates flashing the Engine Control Unit (ECU) with correct data files, ensuring seamless communication and improved functionality.

5. Failure Detection: With its advanced algorithms, the software efficiently detects failures and malfunctions, enabling expedited troubleshooting and resolution.

6. Configuration Data Management: Users can view and change the configuration data of the machine or engine, ensuring compatibility and customization.

7. Professional Maintenance Verification: The software enables users to verify service standards and ensure adherence to professional maintenance protocols.

JCB ServiceMaster 4 Support Models:

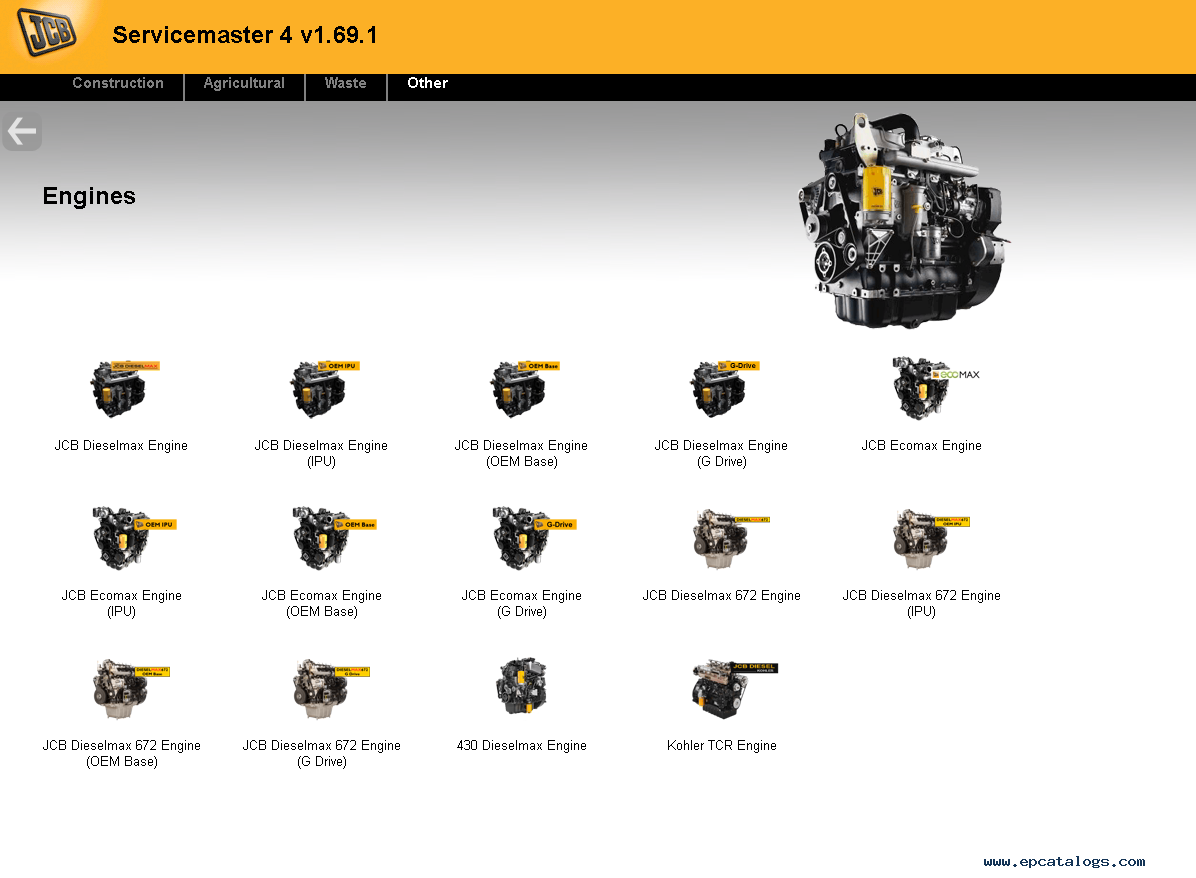

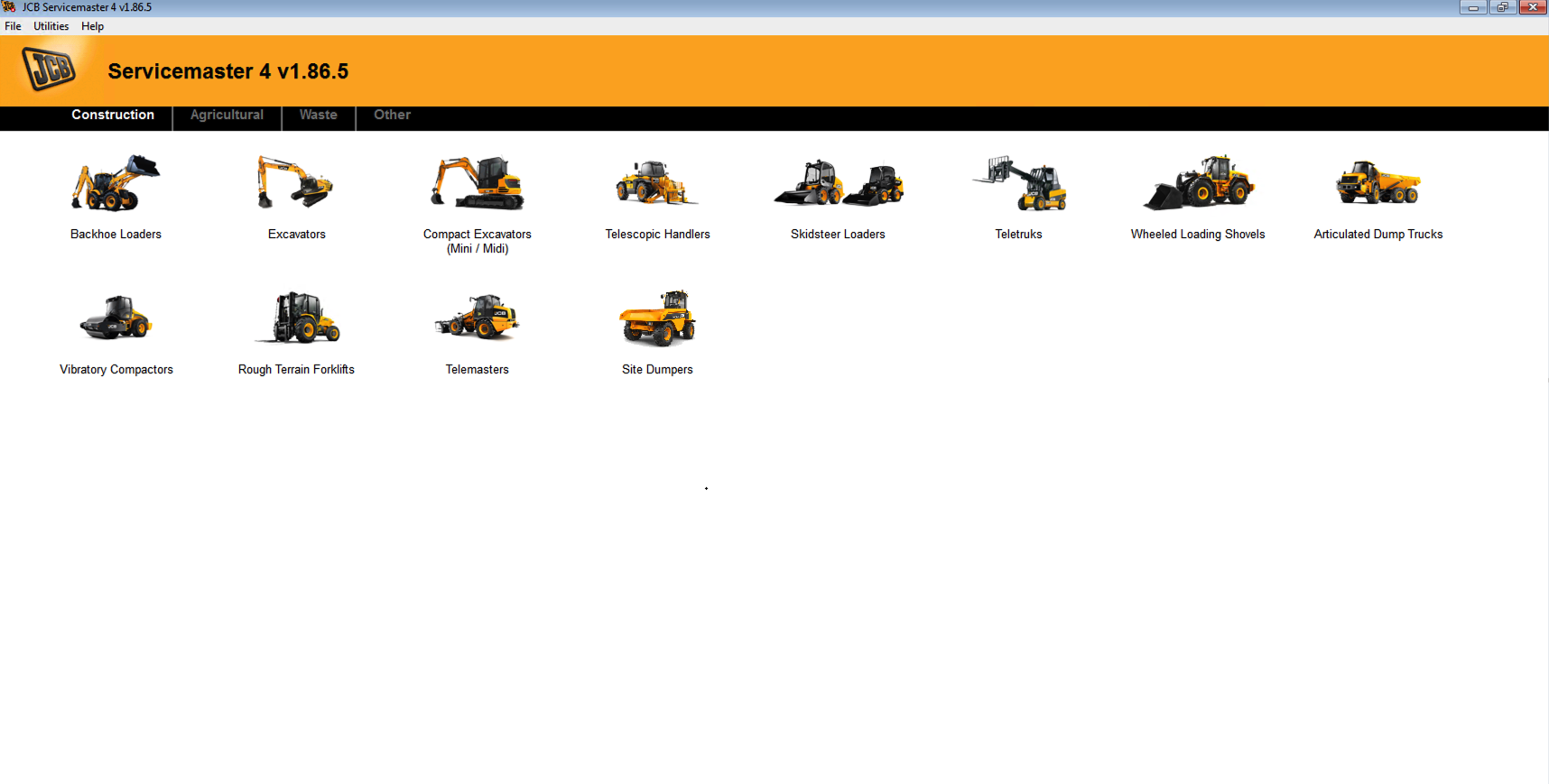

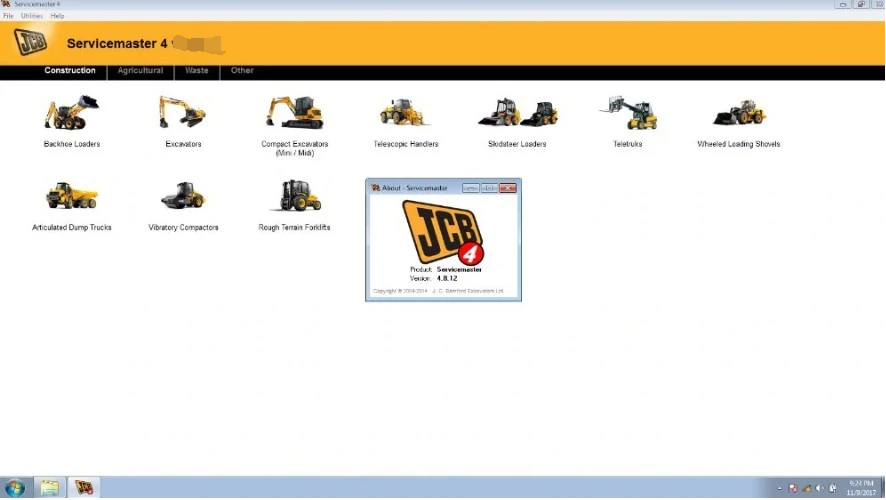

JCB ServiceMaster 4 caters to a wide range of construction, agricultural, waste, and engine models. Some of the supported models include:

1. Construction: Backhoe Loaders, Excavators, Compact Excavators Mini/Midi, Telescopic Handlers, Skid Steer Loaders, Teletruk, Wheeled Loading Shovels, Articulated Dump Trucks, Vibratory Compactors, Rough Terrain Forklifts, Site Dumpers.

2. Agricultural: Fastrac Tractors, Telescopic Handlers, Wheeled Loading Shovels, Telemasters.

3. Waste: Telescopic Handlers, Wheeled Loading Shovels.

4. Engines: JCB Dieselmax Engine, JCB Ecomax Engine, JCB Dieselmax 672 Engine, 430 Dieselmax Engine, JCB Stage V Dieselmax Engine, Kohler TCR Engine, Kohler StageV Engine, among others.

5. Other: Engines, LiveLink, JCB Access, General Generators, Immobilizer.

Computer Requirements:

To ensure smooth operation, JCB ServiceMaster 4 has specific system requirements. These include:

1. Free hard drive space: 50 GB

2. Operating Systems: Windows® 7, 8, 10, and 11 (both 32-bit and 64-bit versions)

Supported Hardware:

JCB ServiceMaster 4 is compatible with various hardware devices, including:

1. JCB Diagnostic Kit (DLA)

2. Nexiq USB Link (Version 1 or 2)

3. DG Technology DPA5

4. Norgone DLA

5. Other RP1210 devices

JCB ServiceMaster 4 stands as a testament to JCB's commitment to providing advanced diagnostic solutions for agricultural machinery and engines. With its user-friendly interface, comprehensive features, and wide-ranging support for models and hardware, this software empowers users to maintain, troubleshoot, and optimize their equipment efficiently. By harnessing the power of JCB ServiceMaster 4, professionals in the industry can enhance their productivity, foster customer trust, and unlock new levels of professionalism and success.