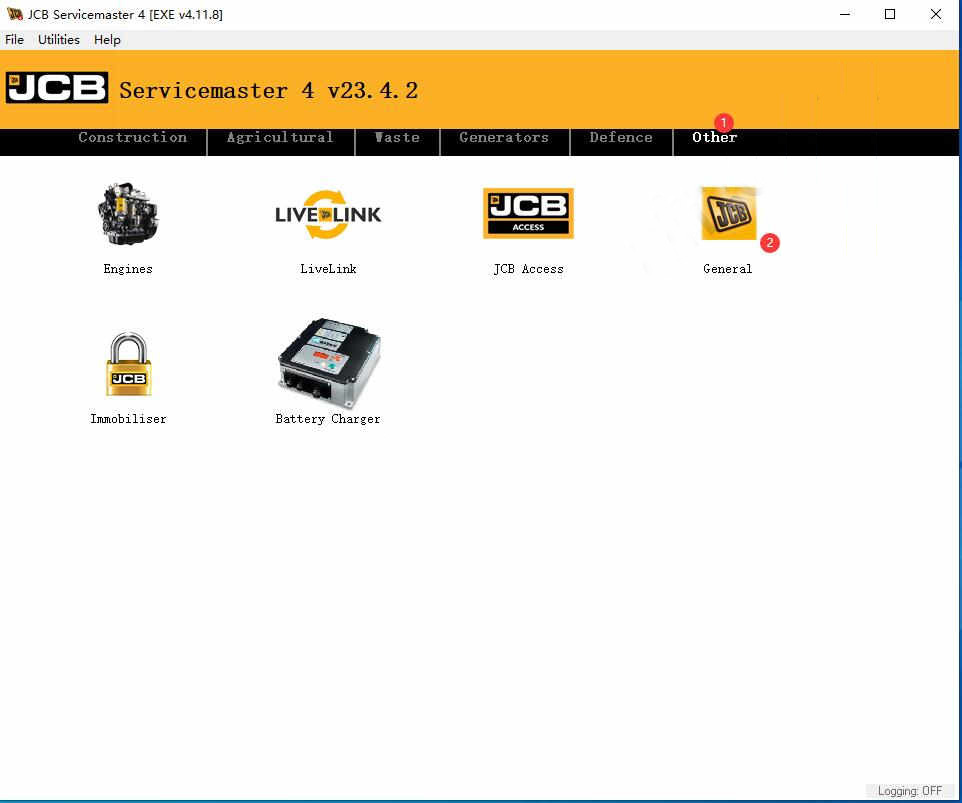

Are you a proud owner or operator of JCB agricultural machinery and engines? If so, then you'll be delighted to know about the powerful diagnostic software called JCB ServiceMaster 4. This software is designed to provide comprehensive support and assistance to users, enhancing their professionalism and earning the trust of their customers.

So, what exactly is JCB ServiceMaster 4? This advanced diagnostic software is specifically developed for JCB agricultural machinery and engines. With its user-friendly and intuitive interface, JCB ServiceMaster 4 offers a wide range of features to facilitate troubleshooting and maintenance tasks.

Let's dive into the details of JCB ServiceMaster 4:

2.1 Software Features:

JCB ServiceMaster 4 comes equipped with a variety of functions to ensure efficient and effective maintenance and troubleshooting processes. Some of its key features include:

- Troubleshooting: Quickly identify and resolve issues with your JCB machinery.

- Standard Test Service: Conduct standard tests to ensure optimal performance.

- View and Edit Generated Data: Access and modify data generated by your machinery.

- ECU Flash Files: Flash the Electronic Control Unit with correct data files.

- Failure Detection: Detect failures promptly for timely repairs.

- Verify Maintenance Standards: Ensure compliance with maintenance standards.

- Configuration Data Changes: View and modify machine configuration data.

- Problem Resolution: Resolve issues effectively.

- Service Standards Verification: Verify adherence to service standards.

- Data Editing: View and edit generated data.

2.2 JCB ServiceMaster 4 Support Models:

JCB ServiceMaster 4 provides support for a wide range of JCB machinery models. Here are some of the supported models:

Construction:

- Backhoe Loaders (Compact Backhoe Loaders, Backhoe Loader 3DX series India)

- Excavators (AMS machines, DECU machines, X series, Excavators (hydrating), India DECU machines).

- Compact Excavators Mini/Midi (8000 Series Machines, NXG Machines)

- Telescopic Handlers (2007-, 2007+, Tier 4, 525-60 Compact Loadall, 430 Dieselmax)

- Skid Steer Loaders (Robot, Skid Steer Loaders, and Compact Track Loaders, Skid Steer Loaders India)

- Teletruk (Tier4 Teletruk)

- Wheeled Loading Shovels (Compact, Medium, Large, Global WLS, Telemasters)

- Articulated Dump Trucks

- Vibratory Compactors (Tier 3, Interim Tier 4, VMT380/430, VM116)

- Rough Terrain Forklifts (Tier 2/3 RTFL, Tier 4 RTFL)

- Telemasters (TM 220, TM 310, TM 320 T4i, TM 320 Tier 4 Final Mk 1, TM 320 Tier 4 Final Mk 2, TM 420 Tier 4 Final)

- Site Dumpers

Agricultural:

- Fastrac Tractors (2000-3000, 3000 Series 2, 3000 Series 3, 3000 Series 4, 4000 Series, 7000 Series, 8250 Series 1, 8250 Series 2, 8000 Series 3, 8000 Series 4)

- Telescopic Handlers (2007-, 2007+, Tier4, 525-60 Compact Loadall)

- Wheeled Loading Shovels (Compact, Medium, Large, Telemasters)

- Telemasters (TM220, TM310, TM320 T4i, TM320 Tier 4 Final Mk 1, TM320 Tier 4 Final Mk2, TM420 Tier 4 Final)

Waste:

- Telescopic Handlers (Tier3, Tier4)

- Wheeled Loading Shovels (427/437/435S T4F, 457 T4F)

Engines:

- JCB Dieselmax Engine (IPU/OEM Base/G Drive)

- JCB Ecomax Engine (IPU/OEM Base/G-Drive)

- JCB Dieselmax 672 Engine (IPU/OEM Base/G-Drive)

- 430 Dieselmax Engine

- JCB Stage V Dieselmax Engine

- JCB Stage V Dieselmax Engine (OEM/IPU)

- Kohler TCR Engine

- Kohler StageV Engine

Other:

- Engines

- LiveLink

- JCB Access

- General Generators

- Immobilizer

2.3 Computer Requirements:

To run JCB ServiceMaster 4 smoothly, make sure your computer meets the following requirements:

- Free hard drive space: 50 GB

- Operating Systems: Windows® 7, 8, 10, and 11 (both 32-bit and 64-bit)

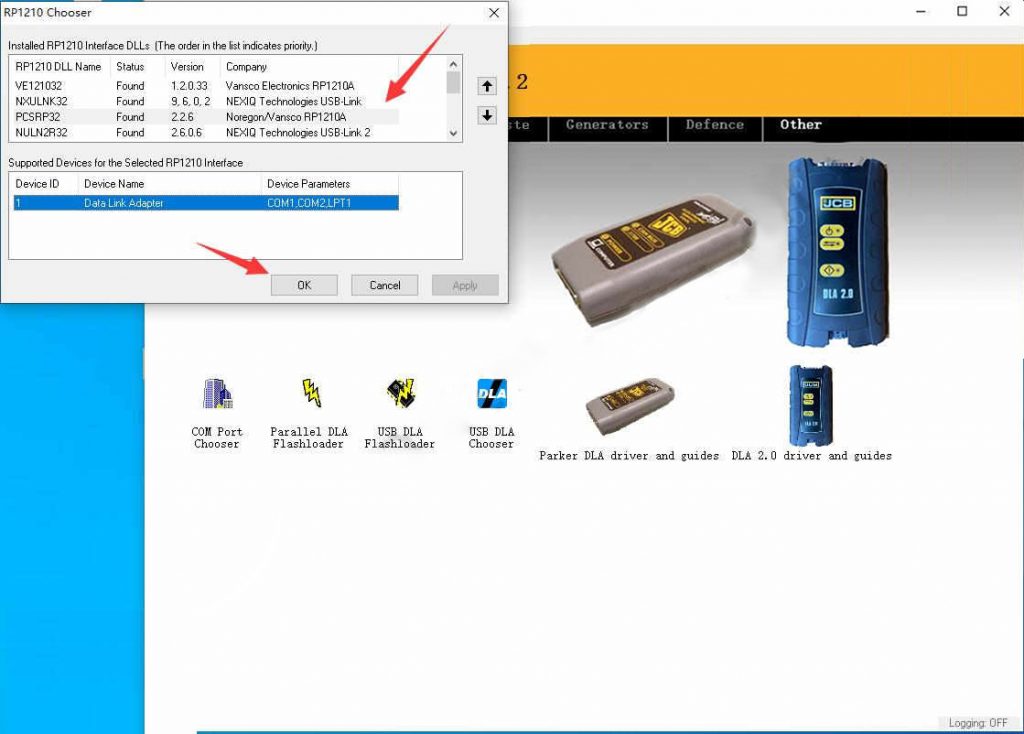

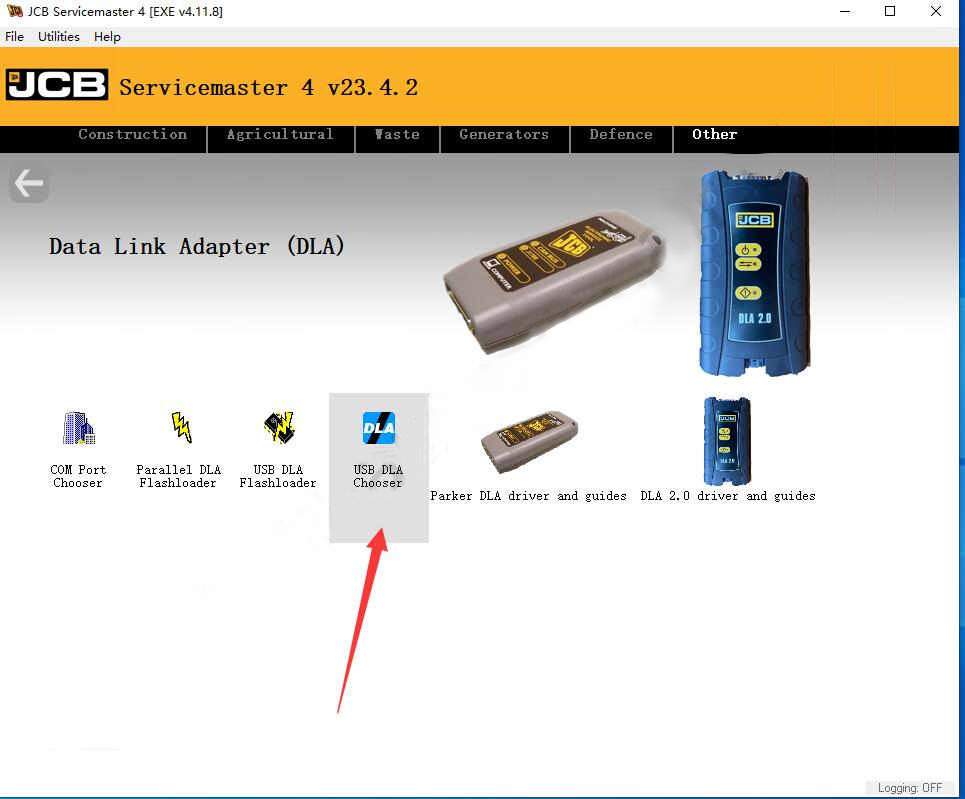

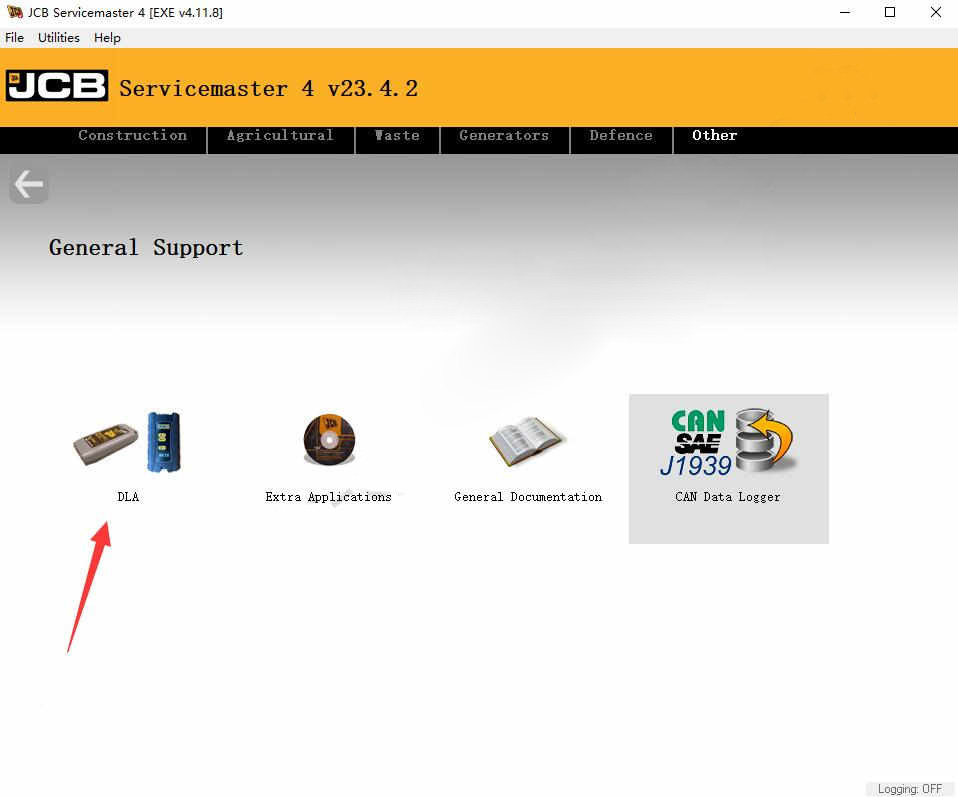

2.4 Supported Hardware:

JCB ServiceMaster 4 is compatible with various hardware devices, including:

- JCB Diagnostic Kit (DLA)

- Nexiq USB Link (Version 1 or 2)

- DG Technology DPA5

- Norgone DLA

- And other RP1210 devices

In conclusion, JCB ServiceMaster 4 is a powerful and user-friendly diagnostic software designed for JCB agricultural machinery and engines. With its extensive features and support for various models, it ensures efficient troubleshooting, maintenance, and overall performance optimization. So, if you're a JCB machinery owner or operator, JCB ServiceMaster 4 is the ultimate companion for all your diagnostic needs.